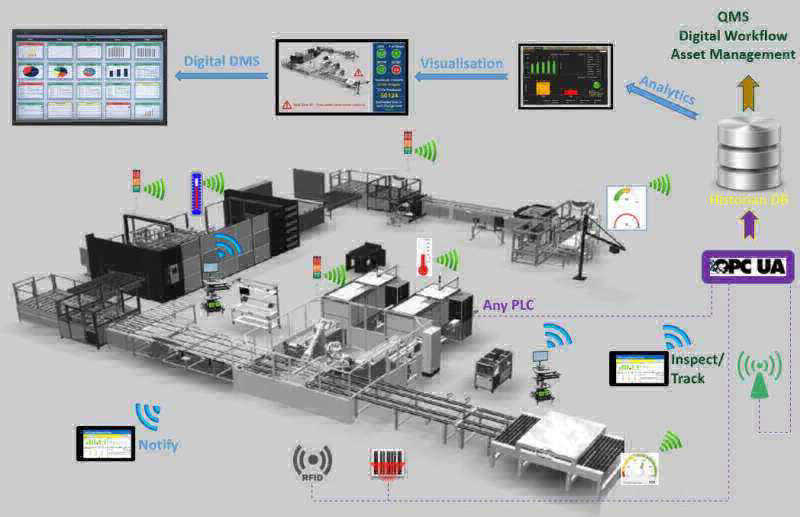

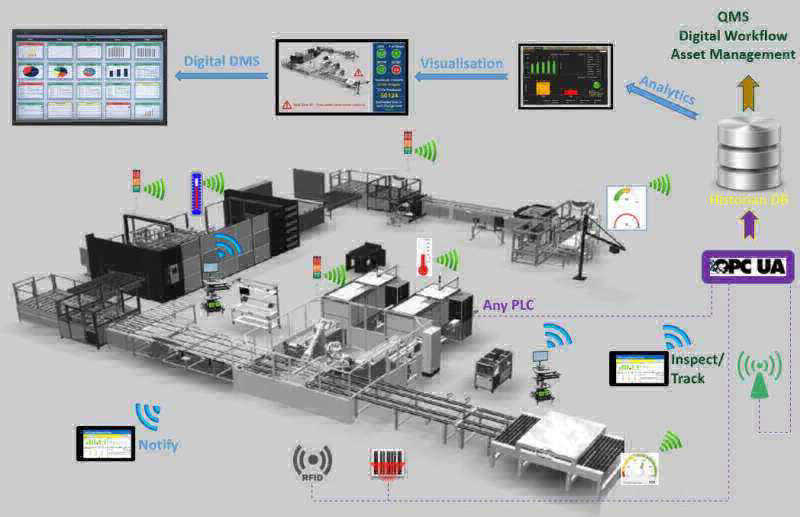

We combine production, information and communication technologies making the manufacturing process intelligent and dynamic.

Decentralized intelligent automation components with embedded software perform their tasks independently, according to the specifications of higher-level systems, and make autonomous decisions.

Distributed intelligence is a basic requirement for modular machines and flexible installations that adjust to changing market and manufacturing conditions.

Connecting and Producing, people, machines, processes and the flow of goods are networked on an ad hoc basis. The software tools simplify multiple steps of the smart manufacturing machine: commissioning, integration and (re) configuration, as well as preventive maintenance of all components, modules and machines.

Open Standards form the basis for horizontal and vertical integration and, therefore, for the continuous exchange of information in value creation networks.

We support open standards such as IEC 61131-3, PLCopen or OPC UA. With multiethernet interfaces we complete the automation allowing a fluidity between TI / TO.

All components and objects are represented as virtual representations in real time throughout the value creation process. These virtual elements are closely linked to their physical counterparts and provide information in context for continuous process improvement in real time.

Automation components and systems record all relevant data using the software and sensors' own functions, and exchange them via multiple Ethernet interfaces. This provides operators and managers with a solid information base for rapid process improvements as production progresses.

The complete network of all automation product components, machines, processes and data, from development and production to recycling, decreases development time and therefore development costs, both for manufacturing lines completely new smart devices as for existing platforms. It also ensures the application-oriented design of all components. Digital lifecycle management is supported with model-based simulations for motion logic systems. This saves time and they can bring new designs to market more quickly.

Security for Industry 4.0 includes protecting people from machine-related risks (security) as well as protecting production facilities and corporate IT / OT from attacks and failures from the surrounding (security) environment. This involves securing confidential data as well as preventing intentional and unintentional malfunction.

Created with Mobirise - Get now